NTD PRODUCTS

The inherent problem with the closing wheel and press wheel pivots is that the cavities that house the pin and bushings are not sealed very well. This allows dust being kicked up by the disc, closing wheel and gauge wheel (especially in dry conditions) to penetrate the pivot cavity. When this dust mixes with the grease it causes the factory seals to break down and it is no longer effective at keeping the dust out.

After the accumulation of acres, the press and closing wheel assemblies can become stiff or even seize up. When this happens it is due to the grease and the abrasive dust mixing together creating a condition referred to as “cake lock failure”.

There are generally two schools of thought on how to avoid this. The first being to not grease the pivots at all. The second being to grease them regularly (every few hundred acres) to purge the dirt from the cavity with fresh clean grease. As you know this is a very time consuming task and frankly not very enjoyable. So while not greasing will most likely keep the pivot moving freely up and down it will also exasperate the wear causing the pivot to become sloppy with excessive lateral movement in the arms. This could result in the closing wheel failing to close the seed slot. It can also cause the press wheel to miss rolling over the seed failing to give the all important seed to soil press which helps to promote consistent germination and uniform emergence.

Even worse is when the press wheel pushes the seed into the side of the slot now requiring the seed to have to emerge through compacted soil rather than from the loosely covered seed slot.

Fortunately, we do have an extremely effective maintenance-friendly, long-term solution. By installing our heavy duty extended wear pivot kits with hardened steel pins, bushings and poly seals, we can fix both the issues of cake lock failure and the lateral movement of the arms.

The two differences in our proven system vs the OEM system is that we use a hardened pin and bushing and heavy duty poly seal with grease overflow channels. The bushing is unique in the fact that it has a step down on the end that faces the outside of the cavity that our poly seal is seated to (pictured here).

After removing the factory pin and bushing and thoroughly cleaning the pivot cavity we seat the slightly oversized interference fit bushing flush with the edge of the cavity and install the pin. Next we install the seal over the step down of the bushing. The seal is seated inside the cavity over the bushing step down creating a pivot cavity that will now keep the dust and dirt from mixing with the grease. The seal also has channels for the grease to escape so there is no risk of over greasing and blowing out the seal. There is also a metal cap that covers the seal when the arm is reinstalled with the new grade 8 hardware.

This will eliminate the previously discussed problems while reducing the need to grease to once a year or every 5,000-7,000 acres depending upon conditions. This system will ensure that the arms will move up and down freely and will not move excessively laterally.

We are very confident in this proven system and back it with an industry leading 3 year/30,000 acre labor and parts warranty.

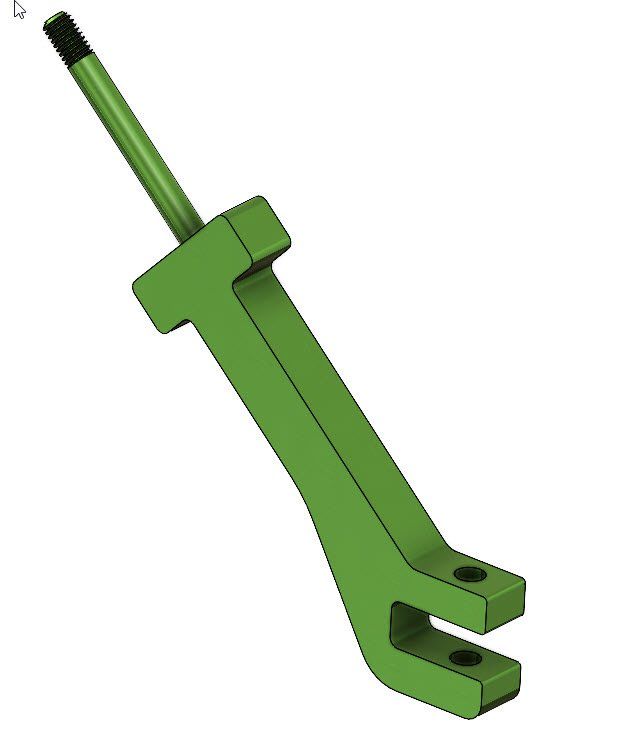

NTD HEAVY DUTY UNIVERSAL ADJUSTER SHAFT FORK HANDLE

The heavy duty universal adjuster shaft fork handle is manufactured by NTD.

- For use on JD 60 & 90-Series Air Drills

- Universal, replaces both left & right configurations

- Half the cost of OEM Depth Handles

- Replaces worn and sloppy Depth Handles

- Powder coated for better rust prevention

Want more information?

© NTD No Till Drill Parts, Services and Repair LLC. All Rights Reserved. - Gonvick, MN

Site Design & Marketing by Flyway Media .

Latest Shows

North Dakota State Fair (July 23-31st) - Minot, ND

BIG IRON (Sept. 15-17) Red River Valley Fair grounds West Fargo ND